Advanced Refrigeration Components

Order Code: 32423

Category: Refrigeration & Air Conditioning Lab

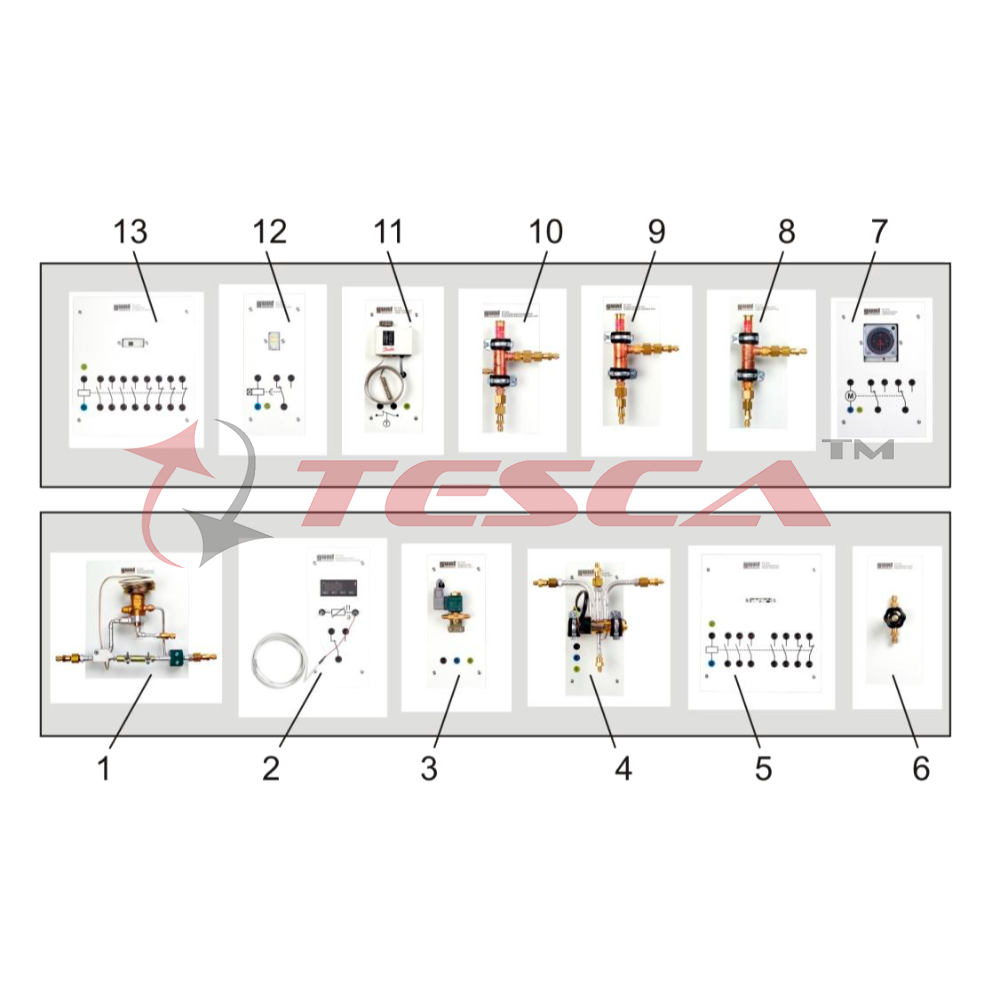

Tesca Advanced Refrigeration Components 32423 enables in conjunction the design and performance of various advanced experiments related to refrigeration. Commercial components are used in practical experiments. These components are mounted on plate

SPECIFICATION

Advanced Refrigeration Components

- Post-injection valve,

- Refrigeration controller,

- Solenoid valve,

- 4/2-way reversing valve,

- Main contactor, 6 valve,

- Defrost timer,

- Capacity controller,

- Start-up controller,

- Evaporation pressure controller,

- Temperature controller,

- Time relay,

- Auxiliary contactor

Features

- Set-up of more complex refrigeration circuits1

- Sophisticated components for advanced experiments

Tesca Advanced Refrigeration Components 32423 enables in conjunction the design and performance of various advanced experiments related to refrigeration.

Commercial components are used in practical experiments. These components are mounted on plates ready to be connected and are arranged clearly in the frame of 32420. The set includes complex refrigeration components, such as capacity controller, start-up controller, defrost timer, 4/2- way reversing valve and refrigeration controller. The 4/2-way reversing valve, for example, is used to reverse the circuit.

This allows for the defrosting of an iced-up evaporator by operating it temporarily as condenser. Manometers provide an insight to the pressure ratios in the refrigeration circuit.

Via pressure and temperature measurements the changes of state of the refrigerant can be tracked and entered into the log p-h diagram. The temperature is measured by inter-laboratory thermometers.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments

Specifications

- Components for the set-up of complex refrigeration circuits in conjunction with RAC 076

- Post-injection valve

- Refrigeration controller with PTC sensor

- Defrost timer, timing interval 30min

- Time relay

- 4/2-way reversing valve, solenoid valves

- Electric thermostat as temperature controller

- Power and auxiliary contactor

Technical Specifications

Rated controller capacity at t0=-10°C, tc=25°C

- Evaporation pressure: 2,8kW at Δp=0,2bar

- Start-up: 5,3kW at Δp=0,2bar

- Capacity: 4,8 kW at offset=0,7bar

Suction line receiver: 0,3L, max. 28bar

Temperature controller: -5...35°C

Refrigeration controller: -40...110°C

Post-injection valve: -45...35°C

Time relay: response delay: 0,05s...100h

Measuring ranges

- Pressure, evaporation: 0...5,5bar

- Intake pressure: 0,2...6bar

- Pressure, capacity controller: 0,2...6bar

Experiments

- Set-up of different refrigeration circuits

- Design, operation and adjustment of components

- Evaporation pressure, start-up, capacity and refrigeration controllers

- Electric thermostat

- Manual valve as expansion element

- Post-injection valve

- Solenoid valve with coil

- 4/2-way reversing valve

- Power and auxiliary contactor

- Time relay

- Defrost timer

- Hot gas defrosting

- Read and understand technical drawings and operating instructions

- Fault finding

Requirements

220 – 240V, 50Hz, AC Power Supply

91-9829132777

91-9829132777